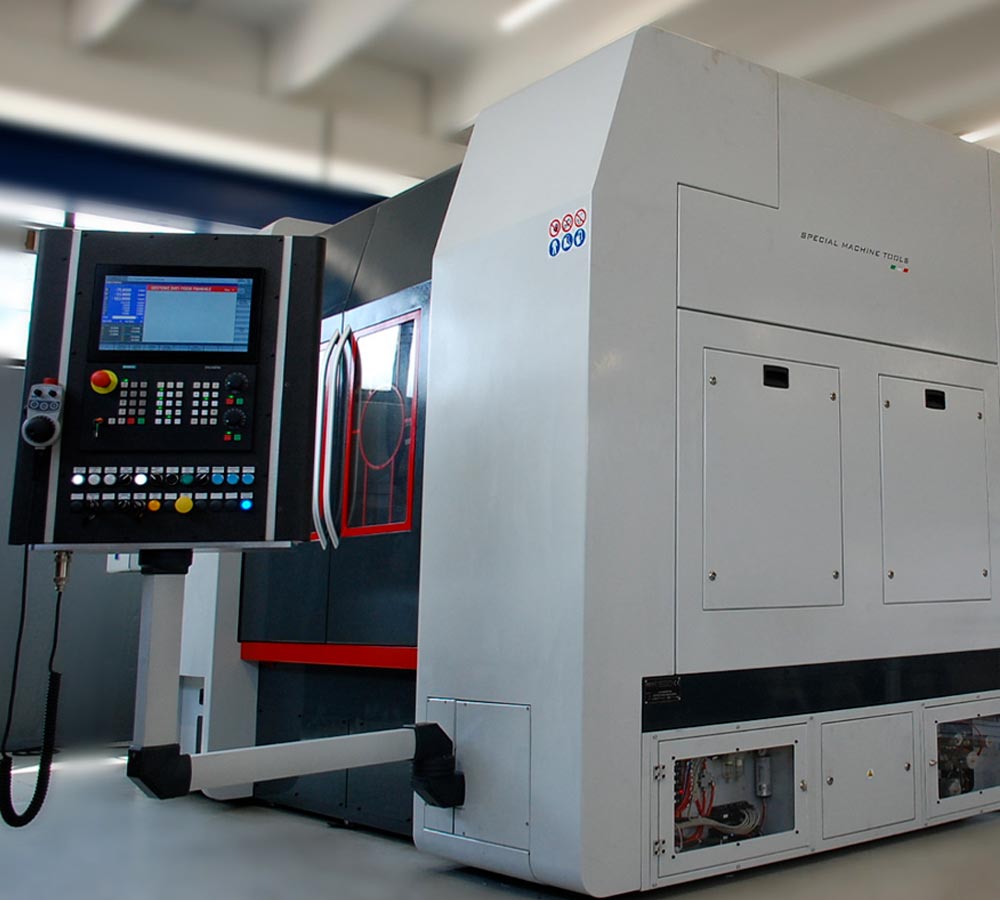

Chamfering grinding machines

SF Series

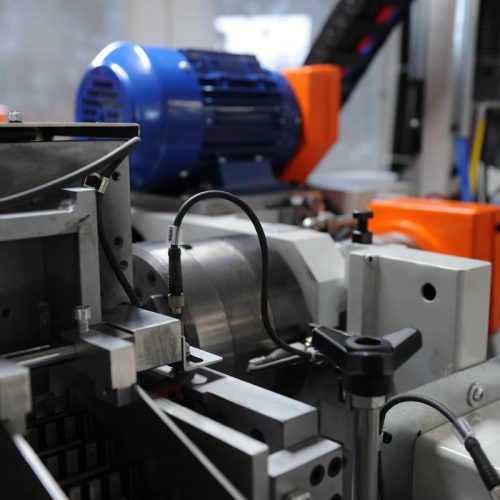

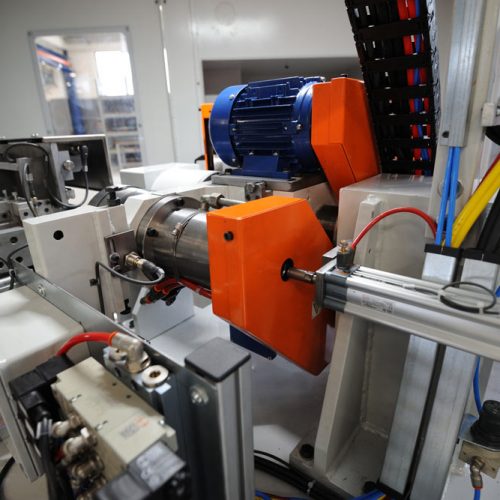

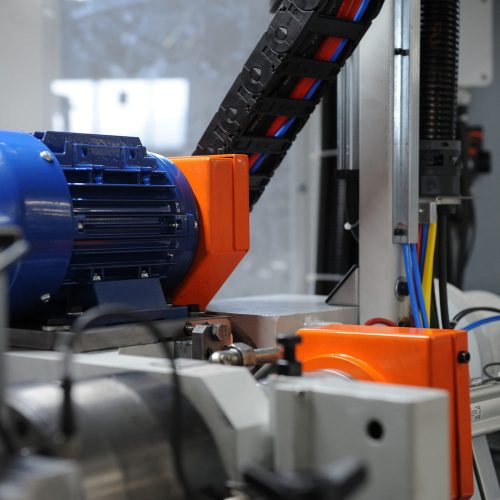

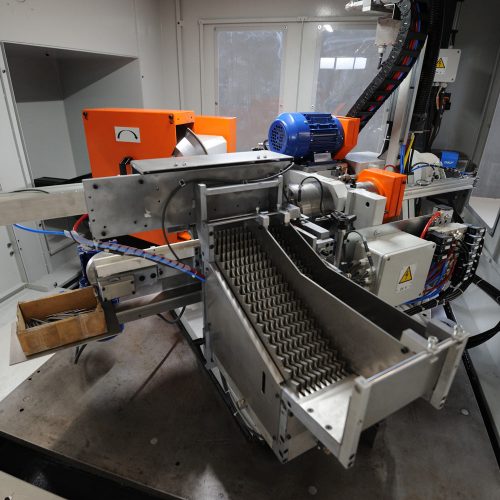

The SF400 chamfering is a transfer style machine dedicated to the additional grinding of various details of semifinished components. It has a single-block cast iron base with a workpiece holder/gripper mounted on cross slides. By interpolating the axis, the workpiece is positioned in front of the grinding wheel and the various types of machining operations are performed in a single clamping.

Operations that can be performed in a single are grinding of tapers, chamfers, face grinding, as well as performing small internal and external machining of simple and complex profiles.

The grinding wheel dressing, when needed, is accomplished by having a dressing diamond in its support mounted steady next to the workpiece clamping fixture, therefore utilizing the same two axis for the dressing operation.

S400X2 and S300X2 machines perform simpler operations such as chamfer or tapers. However, they still allow you to eliminate the loss of idle times of loading and unloading workpieces.

The machine’s software has been designed and produces by SMT technicians with the intent of allowing you to manage all the working processes simply and almost instinctively. Furthermore, customized solutions for loading and unloading of the workpieces allow this machine to work in complete autonomy. The SF series is intended for small to medium production requirements, it guarantees repeatability of the workpiece’s quality and dimensional tolerances, it is ease to operate, simple and economical to maintain. Furthermore, the machine can be equipped with additional accessories such as measuring systems, wheel balancing systems, etc.

Green (less harmful to the environment)

High energy efficiency (energy saver - minimization of energy waste)

Industry 4.0 (digital machine)

| SF400 | S400X2 | S300X3 | |

|---|---|---|---|

| PRODUCTION POSSIBILITY | |||

| Workpieces diameters | Ø2 ÷ Ø16(25)mm | Ø3 ÷ Ø25mm | Ø1,5 ÷ Ø16mm |

| Workpieces length | 15 ÷ 150mm | 15 ÷ 150mm | 15 ÷ 150mm |

| Rotation of the grinding wheel to the workpiece axis | 20° ÷ 90° | 10° ÷ 90° | 10° ÷ 80° |

| CHARACTERISTIC OF GRINDERS - AXIS CNC | |||

| Grinding wheel diameter | Ø400mm | Ø400mm | Ø300-400mm |

| Grinding wheel | 10-30mm | 20-45mm | 6-30mm |

| Grinding wheel hole | Ø127mm | Ø127mm | Ø127mm |

| Grinding wheel peripheral speed | 20 ÷ 45m/s | 20 ÷ 45m/s | 20 ÷ 45m/s |

| Minimum compensation (positive/negative) | 0,001mm | 0,001mm | 0,001mm |

| CNC number of axis | 2 | 2 | 2 |

| MOTORS POWER | |||

| Grinding wheel motor power | 3kW | 5,5kW | 2,2kW |

| Workpiece-holder gripper motor power | 1,5kW | 0,75kW | 0,75kW |

| Installed power | 10kW | 12kW | 10kW |

| GENERAL CHARACTERISTICS | |||

| Total machine weight + services (without accessories) | 4000kg | 5000kg | 6000kg |

| Machine dimensions + services (without accessories) | 2 x 2m | 2 x 2,5m | 2,5 x 2,5m |

Support

Do you need to solve a problem with your centerless grinding machine?