Moveable-center grinding machines

CG.R. Series

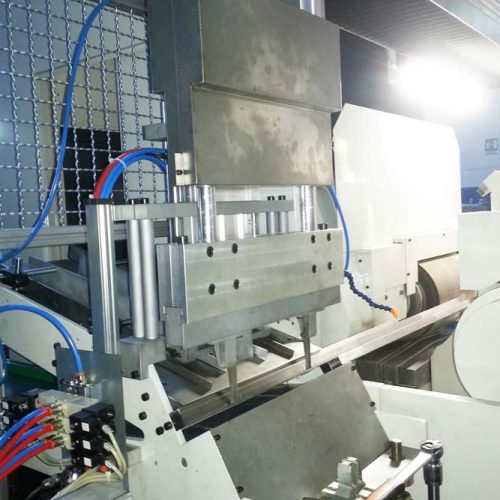

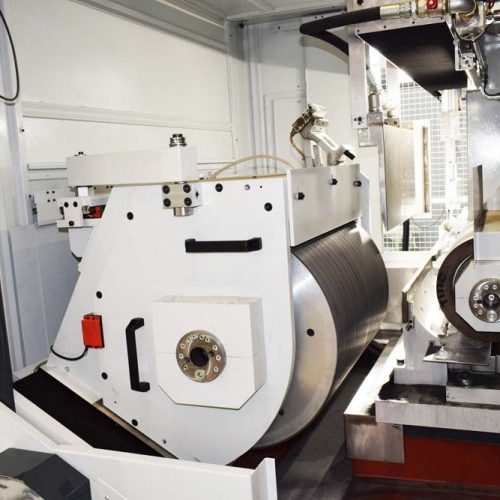

This specific model it is manufactured from of a single-block cast iron base, it is an extraordinarily robust and versatile machine designed to address many if not all of your grinding requirement. The standard machine configuration has three CNC axis that allow you to manage all grinding cycles (through feed and plunge grinding) as well as generate the desired shapes for the grinding wheel and control wheel. The main cross slide of the grinding wheel is inclined 30° to minimize the distance between the slide guideways and the grinding wheel centerline, making the structure more compact and stiffer. In addition, the ability to move the grinding wheel axially “oscillating technology” gives the machine the ability to grind up to a part shoulder as well as obtaining the best possible runout specifically when processing solid carbide bars.

- From CG.R 500/250 to CG.R 600/350 with hydrodynamic grinding wheel spindle, control wheel spindle bronze bushings immersed in oil.

- From CG.R 600/400 to CG.R 600/0 with both special hydrostatic spindles. The fixed shaft and the rotating wheel body alone ensure maximum rigidity.

In all models, the wheels are mounted and removed from the side allowing for an extremely quick change over. Additionally, by having the dressing system mounted directly in front of the wheel, the grinding wheel is dressed (shaped) exactly in the area of the wheel that is in contact with the workpiece. This feature, eliminating geometrical errors that are typical with other form of dressing, allow the machine operator to produce the first piece in tolerance and in a very short time. The specific and straightforward structure of the “CG.R series” also guarantees excellent reliability and a low number of maintenance interventions.

Green (less harmful to the environment)

High energy efficiency (energy saver - minimization of energy waste)

Industry 4.0 (digital machine)

| CG.R 600/200 | CG.R 600/300 | CG.R 600/500 | CG.R600/400 Speciale * (HM) | CG.R600/680 Speciale * (HM) | CG.R 500/250 | |

|---|---|---|---|---|---|---|

| PRODUCTION POSSIBILITY | ||||||

| Workpieces diameters | Ø3 ÷ Ø200mm | Ø3 ÷ Ø300mm | Ø4 ÷ Ø300mm | Ø4 ÷ Ø200mm | Ø4 ÷ Ø200mm | Ø4 ÷ Ø100mm |

| Workpieces lenght with plunge grinding | 200mm | 350mm | 500mm | 400mm | 700mm | 250mm |

| CHARACTERISTIC OF GRINDERS - AXIS CNC | ||||||

| Grinding wheel diameter | Ø610mm | Ø610mm | Ø610mm | Ø610mm | Ø610mm | Ø508mm |

| Grinding wheel width | 200mm | 350mm | 500mm | 400mm | 680mm | 250mm |

| Grinding wheel hole | Ø304,8mm | Ø304,8mm | Ø304,8mm | Ø304,8mm | Ø304,8mm | Ø304,8mm |

| Control wheel diameter | Ø350mm | Ø350mm | Ø350mm | Ø350mm | Ø350mm | Ø300mm |

| Control wheel width | 200mm | 350mm | 400 ÷ 700mm | 400 ÷ 700mm | 700mm | 400mm |

| Control wheel hole | Ø203,2mm | Ø203,2mm | Ø203,2mm | Ø203,2mm | Ø203,2mm | Ø152,4mm |

| Grinding wheel peripheral speed | 20 ÷ 60m/s | 20 ÷ 60m/s | 20 ÷ 60m/s | 20 ÷ 60m/s | 20 ÷ 60m/s | 20 ÷ 60m/s |

| Control wheel speed | 3 ÷ 300r.p.m. | 3 ÷ 300r.p.m. | 3 ÷ 300r.p.m. | 3 ÷ 300r.p.m. | 3 ÷ 300r.p.m. | 3 ÷ 300r.p.m |

| Minimum compensation (positive/negative) | 0,0005mm | 0,0005mm | 0,0005mm | 0,0005mm | 0,0005mm | 0,0005mm |

| CNC axes number (without accessories) | 3 | 3 | 3 | 3 | 3 | 3 |

| MOTORS POWER | ||||||

| Grinding wheel motor power | 22kW | 36kW | 49kW | 49kW | 55kW | 22kW |

| Control wheel motor power | 3kW | 3kW | 5,5kW | 5,5kW | 5,5kW | 3kW |

| Installed power | 42kW | 56kW | 70kW | 70kW | 75kW | 42kW |

| GENERAL CHARACTERISTICS | ||||||

| Total machine weight + services (without accessories) | 9500kg | 10500kg | 13500kg | 13500kg | 14500kg | 11500kg |

| Machine dimensions + services (without accessories) | 4 x 3m | 4 x 3,3m | 4 x 3,3m | 4,3 x 4m | 4,3 x 4m | 3,8 x 3m |

Support

Do you need to solve a problem with your centerless grinding machine?